- Business Query : +91-9560688701

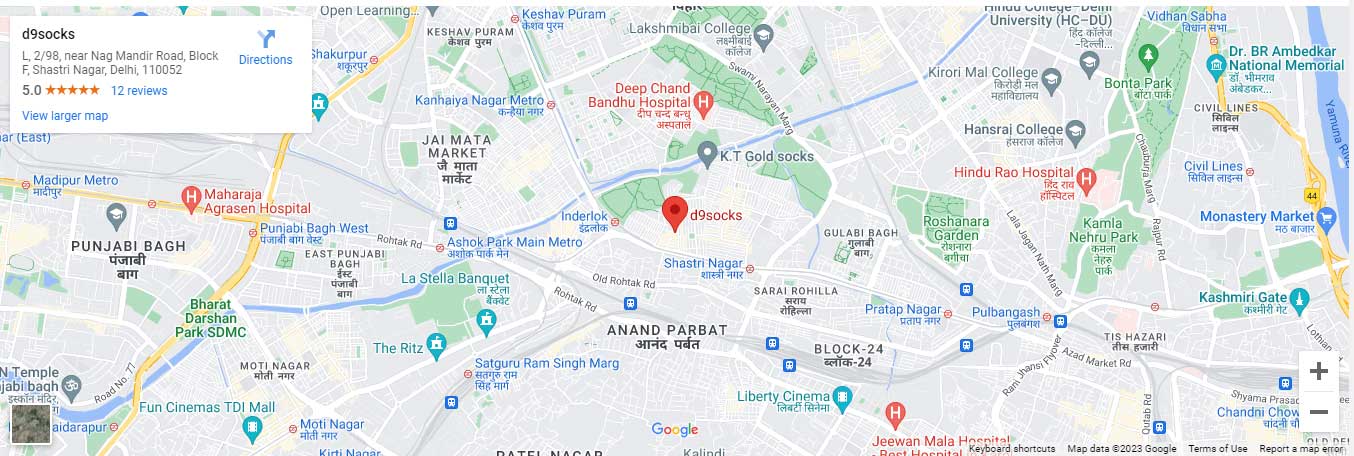

- Locate Us : D-2740/9, Shastri Nagar, New Delhi - 110052

Quality assurance is paramount in the production of D9 Socks to guarantee customer satisfaction and uphold the brand's reputation. To maintain high standards, a comprehensive quality assurance process is crucial.

Firstly, it's imperative to establish precise quality standards that cover various aspects of the socks. These standards encompass the quality of materials used, stitching precision, sizing consistency, color vibrancy, and overall durability. These benchmarks serve as the foundation for assessing the socks' quality throughout production.

Selecting reliable suppliers is the next crucial step in ensuring quality. Building strong partnerships with suppliers known for providing top-quality materials, such as high-grade cotton or synthetic blends for socks, is essential. These suppliers must adhere to rigorous quality control procedures to maintain consistency in the materials supplied.

Random sampling is an essential practice within the quality assurance process. This involves selecting random samples from each production batch and subjecting them to rigorous testing. These tests include visual inspections to detect defects like loose threads or color discrepancies, fit and sizing assessments to ensure consistency across all sizes, material quality evaluations for strength and durability, colorfastness tests to confirm that dyes won't bleed or fade, and stretch and elasticity tests to verify proper fit and comfort. Seam strength tests are also conducted to ensure that the socks are durable and capable of withstanding wear and tear.